MIL-DTL-83413/8D

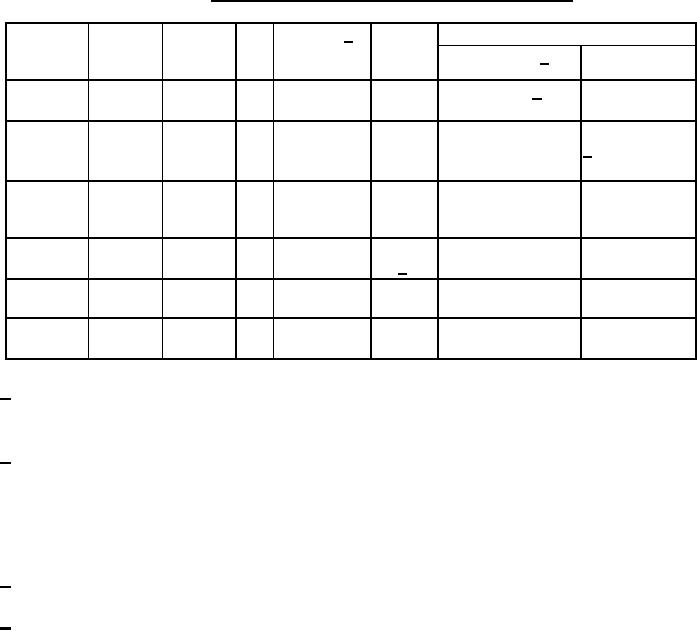

TABLE II. Wire characteristics by jumper assembly type.

Jumper

Material

Stranding Wire Assembly 1/

Tensile

Copper only

assembly

no. x

size resistance

strength Crimping tools 2/

Crimping dies

type

AWG

(max-ohms)

(min-lb)

A, G

Copper

(7 x 37) x 12

.00016xL

110

M22520/5-01 3/ or M22520/5-100

+ .00034 Ω

36

M22520/24-01

B, H

Copper

(7 x 95) x

8

.0006xL

225

SAE-AS5259/1

SAE-AS5259/1

+ .00016 Ω

36

3/

C

Aluminum 37 x

10

.00042xL

75

Not applicable

Not applicable

+ .00110 Ω

0.0167

inch

D

Copper

(7 x 37) x

12

.00016xL

5 to 28 M22520/5-01

M22520/5-100

+ .00034 Ω

36

4/

M22520/24-01

E

Copper

(7 x 37) x

12

.00057

110

M22520/5-01

M22520/5-100

36

M22520/24-01

F

Copper

(7 x 37) x

12

.00016xL

110

M22520/5-01

M22520/5-100

+ .00034 Ω

36

M22520/24-01

1/ Where L = length of the cable assembly in inches. Example: For a 24 inch type A

assembly, assembly resistance = .00016 ohm/inch x 24 inches + .00034Ω = .00418

ohms (max).

2/ Alternate crimping tools which use the specified dies of this table or qualified class II

copper terminal lugs in accordance with SAE-AS7928 (crimped with the tools and

dies used to obtain the class II terminal lug approval), may be used to facilitate high

volume production of copper jumpers. However, either of these options must be pre-

approved by the qualifying activity before qualification tests are initiated on samples

produced using these termination options.

3/ Application: M22520/5-01, /5-100 for use on insulated terminals. M22520/24-01 and

SAE-AS5259/1 for use on uninsulated terminals.

4/ Tensile strength for D jumper assemblies is 5 to 28 lbs, however for the separate

assembly ends: E = 110 lbs and F=110 lbs.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business