MIL-DTL-83413/8D

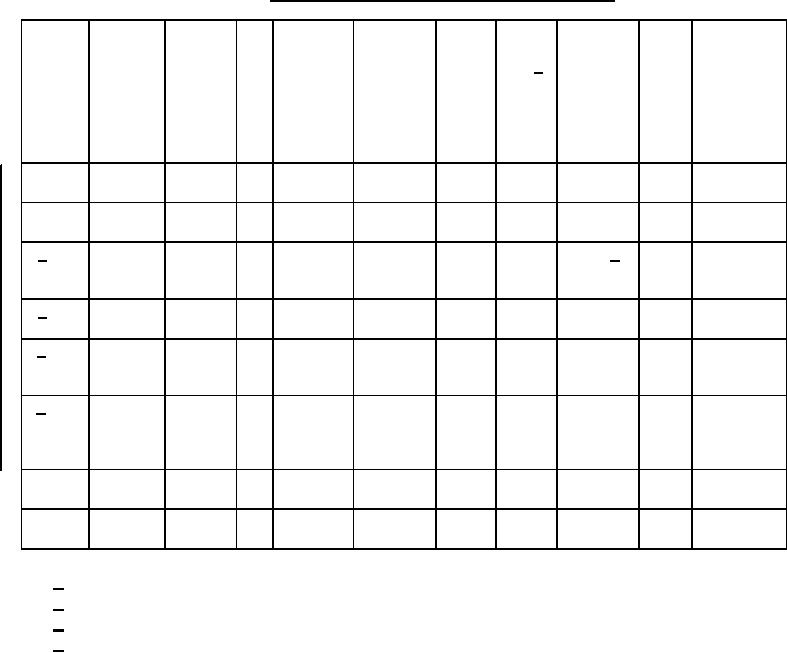

TABLE I. Jumper assembly types and characteristics.

Jumper Construc- Wire and Wire Available

Available Light-

Fuel

Method of

Color

Supersedes

assembly tion type terminal size lug sizes

cable

ning

Compa- attaching

of ID

type

material (see (see tables

tested

band

length,

tible 1/ terminals

table III thru V)

see "L" or

II)

"P"

dimensions

on

figure 1

A

Bonding

Copper

12

A thru J

002-999

No

No

Crimp

No

MS25083-2

band

B

Current

Copper

8

K,L,M,N,T,

002-999

No

No

Crimp

No

MS25083-4

return

U

band

C 2/

Bonding

Aluminum 10 O,P,Q,R,S

003-999

No

Yes

Brazed 4/

Clear

MS25083-1

(aluminum

and -7

only)

D 3/

Quick

Copper

12

A thru G

003-999

No

No

Crimp

No

MS25083-3

disconnect

band

E 3/

Short end Copper

12

A thru G

Fixed

No

No

Crimp

No

MS25083-3S

of quick

length

band

disconnect

F 3/

Long end Copper

12

A thru G

002-999

No

No

Crimp

No

MS25083-3P

of

band

quick

disconnect

G

Bonding Copper

12

A thru J

003-999

Yes

No

Crimp

Yellow

MS25083-5

H

Current

Copper

8

K,L,M,N,T,

003-999

Yes

No

Crimp

Yellow

MS25083-6

return

U

1/

Only fuel compatible jumper assemblies may be used within fuel tank and cells.

2/

Do not use outside fuel tanks and cells.

3/

Inactive for Air Force Airborne use after 9 December 1963.

4/

Dip braze terminals in accordance with AWS-C3.7 Specification for Aluminum

Brazing. A coating is not required on interior strands of the cable, chemical

conversion coating In accordance with MIL-DTL-5541, class 3 shall be applied after

brazing. Inert gas welding using an aluminum based solder or other means of

termination may be used only if approved by the qualifying activity. Aluminum

terminals may be crimped to the cable to facilitate dip brazing. Over crimping shall

be avoided.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business